Published Oct 21, 2016

Creating The TOS Bluetooth Communicator

Creating The TOS Bluetooth Communicator

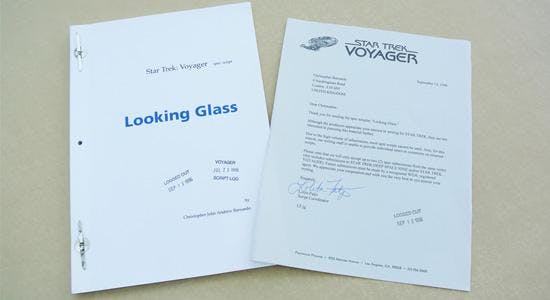

The Star Trek: The Original Series Bluetooth Communicator was two years in the making, but it was born more than 20 years before. Early in 1996, I read in a magazine that the Star Trek: Voyager writers were accepting unsolicited scripts and he decided to write and submit one. Unfortunately, mine was rejected, but I never forgot the dream of somehow working on Star Trek.

Back then I worked with Richard Blakesley at an R&D facility in Cambridge, UK. Together we developed a thin, flexible display technology, and formed a company to manufacture the displays for the best-selling Kameleon remote control.

Nearly a decade later, we set up a new company to design and manufacture another of our joint inventions, the Kymera Wand - the world’s first real magic wand, and The Wand Company was born. With the success of our wand, it was a natural step to move on to develop a remote-control sonic screwdriver, which is after all, really only a science-fiction magic wand, and taking a license from the BBC, The Wand Company entered the world of prop replicas.

At last I had the chance to indulge my Star Trek fantasy when The Wand Company was approached to make an Original Series Phaser and then, the holy grail of props, an Original Series Communicator prop replica.

The Communicator is one of those props that just about everyone, sci-fi fan or not, has heard of. Star Trek inspired a whole generation of engineers and designers to boldly go and develop the future, but 50 years ago when Kirk first flipped open that iconic brass antenna grille and called up the Enterprise to ask Scotty to beam him up, the young viewers who would later go on to develop the mobile telephone suddenly knew that that was what they were going to do. Five decades later, Richard and I also knew that by using Bluetooth technology, we could make our Communicator a success with the fans young and old who cherished the idea of their favorite science-fiction prop made real.

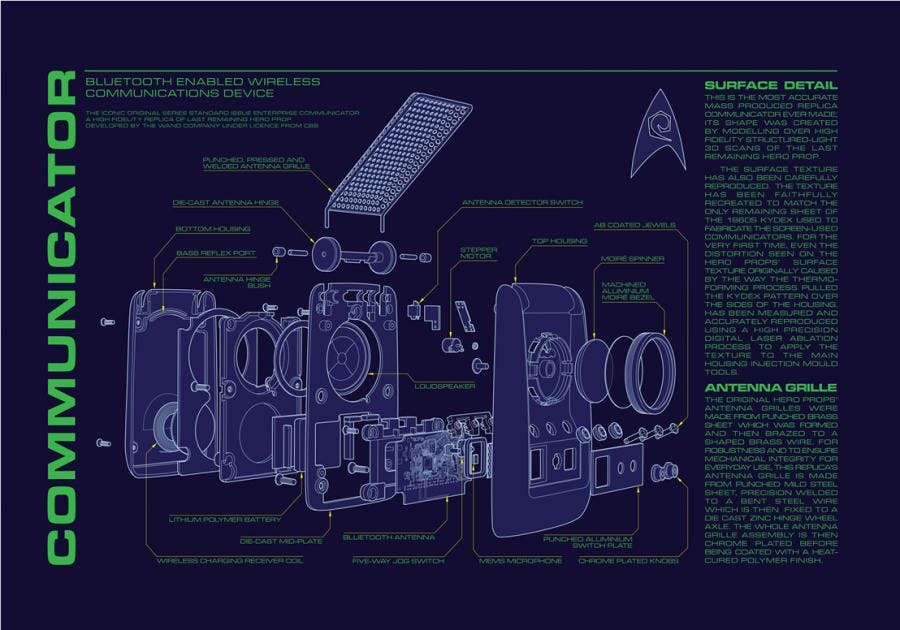

Accuracy was critical, so the first step was to do our research. With thousands of pages of detailed information, herocomm.com was the place to start, but we knew that only seeing the original prop at first hand was going to be good enough. After some negotiation, we were not only able to meet up with the owner of the last known Communicator hero prop, but take it to a 3D scanning studio to get highly detailed scans of the prop itself. The non-destructive scanning process derives the shape of an object by imaging the contours made by thin stripes of light shone over its surface. In a few hours, the technique produced a micron-accurate digital pattern perfect for creating an exact replica.

However, a flawless 3D scan is not the end of the story. Back in the day, all props were made by hand and thus they were not always perfectly formed. Something that looks good enough on screen may not be symmetrical and may have misaligned components, neither of which would look good on a real product. The 3D scans were the beginning of a series of very delicate and careful decisions about how the final product should look and how far to take fidelity. In actual fact, the Communicator is a very well-made prop, but we decided to move the moiré screen bezel 1 mm across to centralize it, and line up and equally space out the three jewel indicators, so as to make a better-looking product.

What separates a toy from a display grade prop replica is the quality of its finishes and the materials. Matching the finish of the mass produced antenna grille to the original hero grille, aged with patina, was not an easy task and required a number of samples to be sent back and forth for review before the final finish was approved. Making the miniature microphone grille, however, wasn’t as much of a challenge. The original hero’s microphone grille used a 1960s transistor radio speaker grille, and as luck would have it original radios still exist. After some searching, one was located and was purchased off ebay and sent to the factory to be copied. Although the original grille was pressed from thin sheet metal in a mass production process, as only a small area of material was needed for all the Communicators to be made, micro machining was used to make the replica grilles.

Even the housing texture had to be meticulously replicated right down to the pattern stretch caused by the way that the original prop case had been made by thermoforming a sheet of patterned plastic over a "buck." And because the original texture was made up of miniature sculpted troughs and bumps, simple etching on the inside of the housing tooling was not sufficient to reproduce the pattern. Instead, a new laser etching process was used to create the texture on the inside of the tooling. Although expensive, the process allowed us to control the exact design of the texture and make sure it was as accurate as possible.

In order to make the Communicator look and feel as authentic as possible, wireless charging was selected over a simpler USB plug and socket arrangement, leaving the outside of the Communicator case free from an unsightly USB plug socket. And Richard set about designing the hardware needed to embed the charging coil in the display stand.

One of the most exciting aspects of working on a prop replica is designing the accessories that go with it. Whereas the original prop determines the outward design of the Communicator itself, items like the charging-display stand, soft carry case and hard-shell transit case all need to be designed from scratch. Importantly for the fans, these elements need to appear authentic, as if they might have existed with the product, but no canon exists to drive their design. For the carry case, various options were considered, including a semi-rigid, compact camera-style case before the leatherette pouch was finally agreed on as the most-elegant solution.

While I was designing the case and accessories and they were being refined by the factory for manufacture, Richard developed and designed the hardware and software to bring the Communicator alive. Typically, Mobile phone development teams run to hundreds strong, so creating a mobile phone quality system and making sure it passed all the statutory regulations for such a device was a significant challenge for our tiny team.

Finally, in the spring of 2016, production started. The Communicators are made in China by skilled operatives working in excellent conditions who pretty much assemble each unit by hand using purpose built jigs and specialist equipment.

So there you have it; 50 years after the Communicator first saw the light of day on a distant planet in Kirk’s hand in 2265, after 20 years of dreaming and two years of hard work, finally a working Communicator was launched to happy fans, 200 years ahead of schedule.

NOTE: The Star Trek: The Original Series Bluetooth Communicator is available now via Best Buy and ThinkGeek.